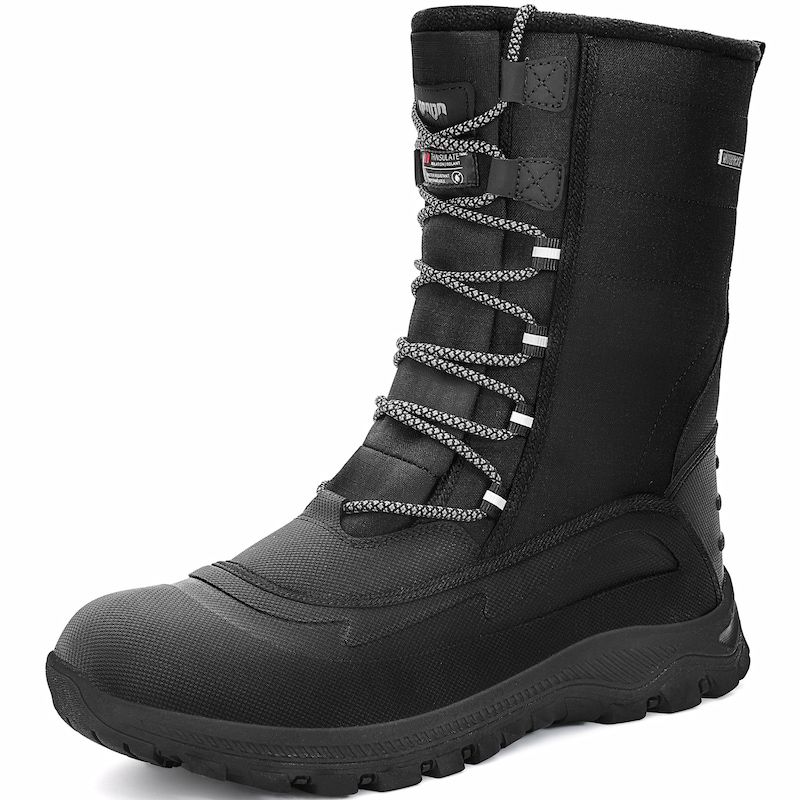

Das von Ihnen gesuchte Paar Damen-Küchenschuhe soll hervorragende Funktionalität und Komfort in der Küchenumgebung bieten. Diese Schuhe sind speziell auf die Anforderungen einer geschäftigen Küche zugeschnitten und gewährleisten Sicherheit und Bewegungsfreiheit für den Träger.

Merkmale:

-

Ölbeständig: Die Schuhe sind so konzipiert, dass sie Ölflecken und -spritzern standhalten und Ihnen auf rutschigen Küchenböden sicheren Halt bieten.

-

Antistatisch: Sie verhindern den Aufbau statischer Elektrizität und verringern so das Risiko statischer Stöße in der Küchenumgebung.

-

Rutschfest: Die rutschfesten Außensohlen bieten hervorragende Traktion auf nassen und fettigen Oberflächen, erhöhen die Stabilität und verhindern Ausrutschen und Stürze.

-

Wasserfest: Die Schuhe sind wasserabweisend und halten Ihre Füße auch bei Nässe trocken und bequem.

-

Leicht: Diese aus leichten Materialien gefertigten Schuhe lassen sich problemlos über viele Stunden hinweg tragen, ohne dass es zu Ermüdungserscheinungen kommt.

-

Komfortabel: Die Schuhe sind mit gepolsterten Einlegesohlen und einer stützenden Konstruktion auf Komfort ausgelegt, sodass Sie während Ihrer Schicht bequem auf den Beinen bleiben können.

-

Material: Diese aus Fly-Knit-Material gefertigten Schuhe bieten Atmungsaktivität und Flexibilität und behalten gleichzeitig die Haltbarkeit für den Langzeitgebrauch bei.

Diese Damen-Küchenschuhe sind eine perfekte Mischung aus Funktionalität und Komfort und machen sie zu einem unverzichtbaren Accessoire für alle, die in der Küche arbeiten.

Häufig gestellte Fragen

Sind Sie eine Fabrik oder ein Handelsunternehmen?

Wir sind eine Fabrik, die sich auf die Herstellung hochwertiger wasserdichter Schuhe spezialisiert hat. Außerdem haben wir unsere eigene Marke – @R CORD, und Sie können unsere Produkte auf der Amazon-Plattform finden.

Bieten Sie OEM/ODM-Dienste an?

Wir können Schuhe nach den spezifischen Anforderungen unserer Kunden herstellen und auch Schuhe unter unserer eigenen Marke herstellen.

Was ist Ihre Mindestbestellmenge?

Normalerweise beträgt unsere Mindestbestellmenge 1000 Paare/Farbe/Stil.

Können Sie Muster Ihrer Schuhe zur Verfügung stellen?

Mit unseren vorhandenen Materialien, Sohlenformen und Leisten können wir in der Regel innerhalb von 3 Tagen ein Muster fertigstellen. Wenn jedoch neue Materialien benötigt werden, kann die Fertigstellung der Probe bis zu 15 Tage dauern. Bitte beachten Sie, dass Mustergebühren und Versandkosten erhoben werden, diese Gebühren jedoch erstattet werden, sobald eine Großbestellung aufgegeben wird.

Was ist Ihre Vorlaufzeit für die Produktion?

Die Lieferzeit hängt von der Bestellmenge ab und liegt normalerweise zwischen 60 und 75 Tagen bei einer Bestellung von 10.000 Paaren. Sollte es zu einer Verzögerung kommen, werden wir Sie proaktiv über den Status informieren und mögliche Lösungen im Voraus anbieten.

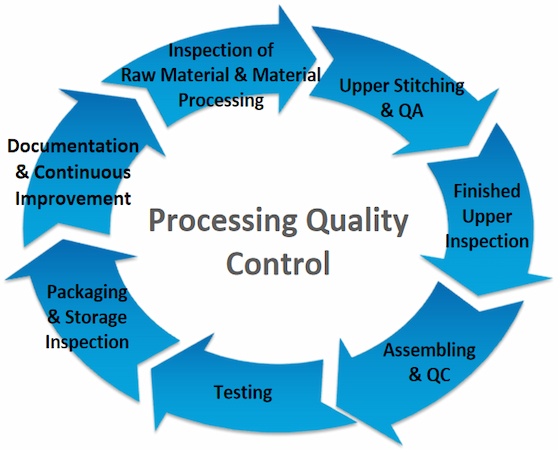

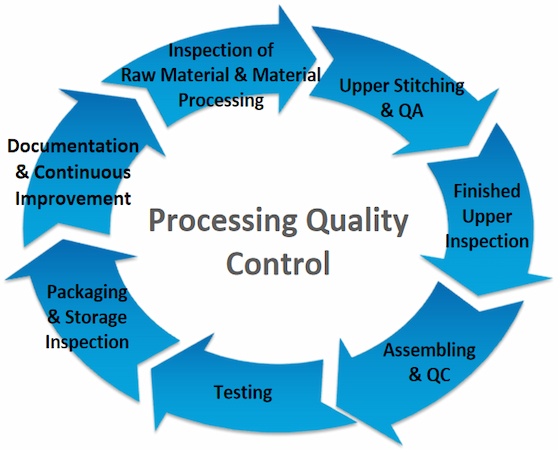

Wie sieht Ihr Qualitätskontrollprozess aus?

Unser professionelles QA/QC-Team überwacht jeden Aspekt des Produktionsprozesses, von der Prüfung eingehender Materialien über die Durchführung von In-Process- und Fertigproduktinspektionen, die Durchführung von Tests, die Verwaltung von Korrekturen und Nacharbeiten sowie die Überwachung von Verpackung und Versand, um sicherzustellen, dass jede Bestellung den höchsten Anforderungen entspricht Qualitätsstandards.

Können Sie Schuhe nach unserem eigenen Design und unseren Vorgaben herstellen?

Wir können unsere Schuhe an die spezifischen Bedürfnisse und Vorlieben jedes Kunden anpassen, einschließlich Größe, Farbe und Design.

Welche Zahlungsmethoden akzeptieren Sie?

Wir akzeptieren TT (30 % Anzahlung, 70 % gegen BL-Kopie) oder LC bei Sicht.

Qualitätskontrollprozess

1. Eingangskontrolle des Rohmaterials: Überprüfung der Materialien auf etwaige Mängel, wie z Farbvariation, Textur und Dicke.

2.In-Prozess-Inspektion: Das Qualitätskontrollteam prüft Schnitt, Naht, Zwicken usw Veredelungsprozesse. Das Team prüft auch etwaige Mängel wie z ungleichmäßige Nähte, Kleberfleckenund Schäden am Material.

3. Vorabkontrolle: Auf Kratzer, Flecken und Unebenheiten prüfen.

4. Endkontrolle: Das QC-Team prüft jedes Paar Schuhe auf etwaige Mängel, wie z Probleme beim Nähen, falsche Größe, und Schaden. Das Team überprüft auch das Gesamterscheinungsbild der Schuhe, einschließlich Farbe, Textur und Verarbeitung.

5. Verpackungsinspektion: Das Team prüft die Verpackung auf etwaige Mängel, wie z falsche Kennzeichnung, falsche Verpackungsmaterialien und Schäden.

6. Testen: Durchführung von Tests, um sicherzustellen, dass die Schuhe die erforderlichen Leistungsstandards erfüllen. Die Tests können Abriebfestigkeit, Biegefestigkeit, Wasserbeständigkeit und Kompression umfassen.

7. Dokumentation und kontinuierliche Verbesserung: Aufzeichnung aller Inspektionen, Tests usw Korrekturmaßnahmen genommen. Der QC-Team analysiert die Dokumentation und identifiziert Verbesserungsmöglichkeiten.

Fabrikbilder

Fabrikauftritt

Arbeitsplatz

Büro

Besprechungsraum

Schneiden

Schneidemaschine

Elektronische Schneidemaschine

Linienmarkierungsmaschine

Verpackung

Lagerraum

Ladetechnik

Laden

Warum uns wählen?

Erfahrung

ErfahrungMit 30 Jahren Erfahrung in der Schuhindustrie verfügen wir über einen großen Wissens- und Erfahrungsschatz, der genutzt werden kann, um qualitativ hochwertige Schuhe effizient und effektiv herzustellen.

Qualität

QualitätWir verwenden nur die besten Materialien und Produktionstechniken, um sicherzustellen, dass unsere Schuhe langlebig, bequem und stilvoll sind.

Anpassung

AnpassungWir können unsere Schuhe an die spezifischen Bedürfnisse und Vorlieben jedes Kunden anpassen, einschließlich Größe, Farbe und Design.

Nachhaltigkeit

NachhaltigkeitWir engagieren uns für Nachhaltigkeit, indem wir nach Möglichkeit umweltfreundliche Materialien und Produktionsprozesse verwenden, um die Umweltauswirkungen unserer Produkte zu minimieren.

Märkte

MärkteUnsere starke Präsenz in Schlüsselmärkten, darunter den Vereinigten Staaten, Kanada, Russland und Europa, zeigt unsere Fähigkeit, die Bedürfnisse von Kunden in verschiedenen Märkten zu erfüllen und ihnen die Sicherheit zu geben, weltweit hochwertige Schuhe zu liefern.

Team

TeamZu unserem Team gehören erfahrene Designer, Handwerker und Qualitätskontrollpersonal, die zusammenarbeiten, um sicherzustellen, dass unsere Schuhe den höchsten Qualitäts- und Qualitätsstandard entsprechen Komfort.

Global

Global